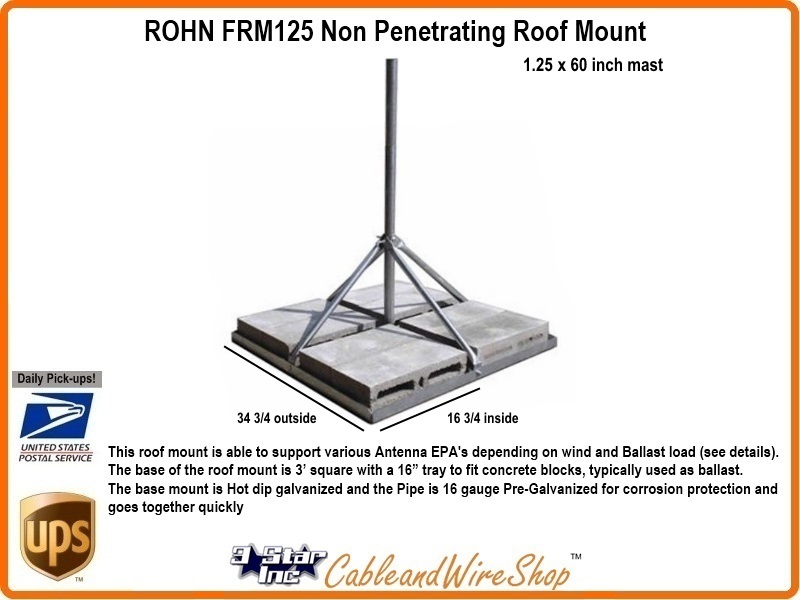

Non penetrative mechanical fixing this method is where the mounting system sits completely separate atop the waterproofing via substructures that are held onto the roof through mounting plates and welding or bonding overlying membrane sleeves to the uppermost layer of the waterproof covering.

Non ballasted roof.

For built up roofing the gravel was generally 25 5 inches in diameter.

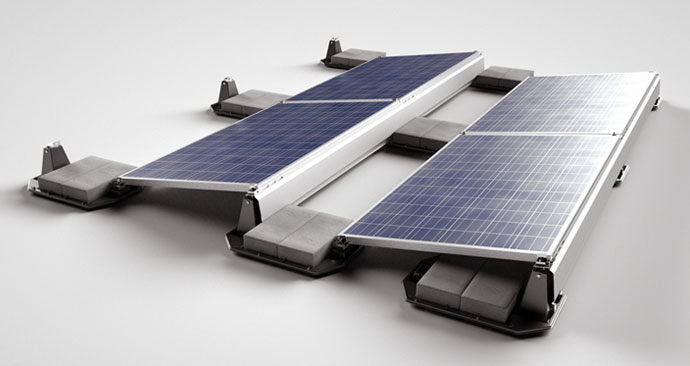

The system is delivered in compact form to save logistics cost unfold at site saves valuable time.

The stones used in ballasted roofing are generally 1 5 2 5 inches in diameter and applied in a thicker layer.

Ballasted roof systems are simultaneously a roofer s best friend and arch nemesis.

The weight of a roofing system varies depending on components used.

After combining the weight of components i e.

No need to anchor and damage the roof membrance.

Corigy solar non penetrating ballast solar racking is designed for solar mounting on commercial or residential flat roof.

What is the average unit weight of non ballasted epdm roofing systems.

Section 1609 is title wind loads and contains the wind design speed maps and other pertinent roof wind uplift resistance requirements.

The gravel used in built up roofing what the roofing contractors were used to was not the same as that used in a ballasted roof.

Simply put a ballasted roof is easy to install and basically guaranteed maintenance work for a roofer.

Somebody walking on the roof will undoubtedly step on the ballast and put a hole in the membrane.